- Hot product search£ºA duster¡¢Pulse bag filter¡¢Low pressure¡¢Pulverized machine¡¢Grinding machine¡¢Fly ash ¡¢Dryer

Contacts£ºManager Wang

Tel£º0515-80616558

Fax£º0515-80616658

After-sale service£º0515-86358288

E-mail£ºjsyfhb@163.com

Your current position: home page > Product

First, an overview

With the increasing maturity and popularization of the comprehensive utilization technology of fly ash in China, the comprehensive utilization of fly ash is not only limited to the requirements of environmental protection, but the huge economic benefits of the comprehensive utilization of fly ash have been embodied. In China's southeastern coastal areas and some developed areas, the fine ash of fly ash has even been in short supply. The fineness of coal ash discharged from a large number of coal-fired power plants in China is usually changed from 20% to 50% (325 mesh sieves), which can not reach the first grade ash and two grade ash requirements stipulated by the national standard (GB196-2005). In general, the dry separation technology of fly ash is widely used in power plants to separate coarse and fine gray from the raw ash and obtain good economic benefits. But after the separation, the coarse ash (about 65% of the average fineness) has not been fully utilized. Generally, it is still in place or sold at a low price, and even the burden of the enterprise. The ultra fine grinder of the raw ash or the coarse ash after the separation is used for ultra-fine grinding to make it have a certain water hard activity and produce high grade superfine ash, which can make high performance concrete, so as to achieve the purpose of full utilization of fly ash and create greater economic benefit.

It has been used for many years in the cement industry by grinding the powder with ball mill. The technology is mature, and the mill product has been relatively serialized. Drawing on the principle and structure of various high and high yield cement mills at home and abroad, the research department of Yancheng City salt rich company combined the Department of material science of Nanjing University of Technology, the most famous University of fly ash, which has successfully developed a special ball mill for fine grinding of fly ash, which will grind the original ash or coarse ash discharged from the coal fired power plant. To achieve the fineness of the finished product. After the ball mill, a sorting equipment is added, and the fly ash grinded by the ball mill is selected. After sorting, the coarse ash is returned to the ball mill for superfine grinding, and the advanced admixture (fine powder) can be produced to make up the high performance concrete, which greatly improves the economic benefit of the comprehensive utilization of the fly ash and can realize the whole fly ash. Comprehensive utilization of the Department.

Two. Summary of fly ash grinding system

1. A brief introduction to the process of the grinding system

The system of FY series fly ash superfine ball mill mainly consists of the original ash bin, the auxiliary bin, the spiral feeder, the electronic measurement, the fly ash special ball mill, the pulverizing machine, the air box pulse bag filter, the fan, the screw conveyor, the bucket elevator, the feeder and control system.

The system is directly from the original ash bin to take the ash, through the spiral feeder, the electronic weighing is transported into the grinding head hoist after the weight of the air slots, and the hoist is fed into the pulverized machine for the grinding. The coarse ash after the separation is sent into the mill inlet through the air inclined trough and enters the grinding mill. The material is contained in the grinding machine after the mill. A large number of fine ash, once again fed by the hoist to the pulverized machine, is sent to the finished ash bank through the subsequent conveying equipment, and the tail of the mill is equipped with a dust collecting system to collect dust. This closed road grinding process can increase the output of 30 to 40% when compared with the open road (no pulverized machine) system. It is the fine and deep processing of the fly ash. Ideal equipment.

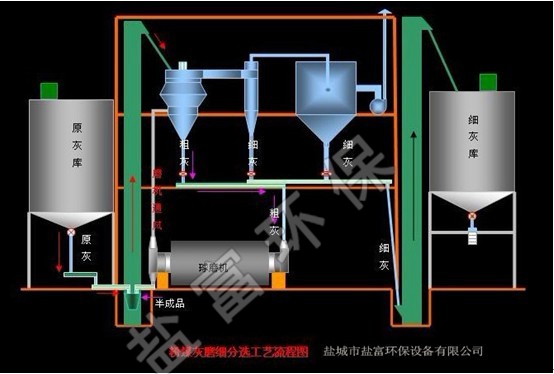

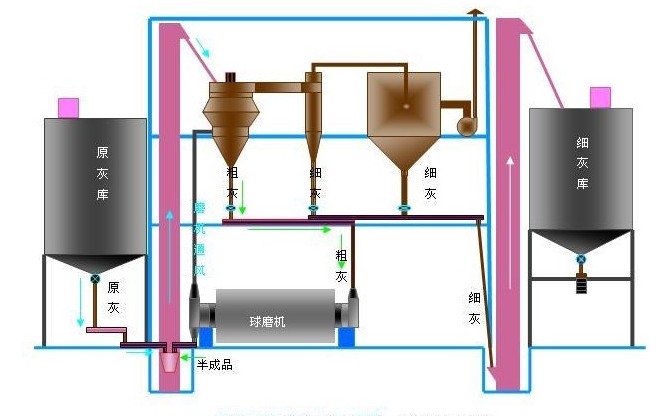

2. The flow chart of the grinding system (attached)

Fly ash grinding and separation process show that the fly ash grinding system mainly consists of the original ash silo, impeller feeder, electronic measurement, fly ash special ball mill, pulverizing machine, air box pulse bag filter, air guide, screw conveyor, bucket elevator, feeder, control system and so on. The system is directly removed from the original ash bin and supplied by the impeller feeder. The electronic weighing is conveyed by the screw conveyor into the mill tail hoist after the electronic weighing, and the fly ash is fed by the hoist to the pulverized machine for grinding. The coarse ash after the separation is sent into the mill inlet through a screw conveyor, and is lapped into the ball mill and lapped after a mill. There are a lot of fine ash in the material, and then the separator is fed by the hoist, and the fine ash is sent into the finished ash bank through the subsequent screw conveyor. The mill ventilation and dust removal is shared with the fine powder bag filter of the pulverized machine. This closed road grinding technology is compared with the open road (no powder separator) system to increase the output of 30 to 40%. .

Three. Transform the ordinary ball mill into a special grinding machine for fly ash.

The mill barrel is generally divided into two silos. In view of the particle size composition and the grinding property of the fly ash or coarse ash and mixture, the modification of the ultra-fine grinding of fly ash for the inner device of the ball mill is carried out. The ZG series of propeller shaped fly ash mill produced by our company is used for the system transformation of the ball mill, so that it is more suitable for the powder. The closed production process of the fine coal ash.

A series of YF propeller coal ash grinding double screen separates plate parameters:

(1) grate plate and belt hole panel:

Casting material: Mn Cr alloy grate: 5mm

(2) the sieve frame:

The fly ash mill is special for the imported wear-resistant steel plate.

(3) sieve plate:

Stamping material: Delta 3mm stainless steel seams: 1.2 ~ 1.5mm

Standard parts: (cylinder and screen connecting bolts and nuts) depending on the specifications of the mill.

Two specific reform measures:

(1) the use of fly ash special double screen partition board to replace the original septum plate, the grate gap of the barn is 5mm, and the sieving seam of the middle stainless steel sieve plate is 1.2mm, which can effectively control the particle size of the two silo particles, speed up a qualified particle into two storehouses for high efficiency grinding, and reduce the over grinding in one warehouse.

(2) according to the grinding degree and the length of the pulverized coal ash to determine the length of the mill, usually a steel ball of 20 to 50 of the ball is used to match the ball, and the two bin is forged with a small size of 8 to 16 small sizes, because the surface area of the micro forging is relatively large, and the fine particle size can be effectively grinded and the velocity of the material in the grinding mill can be slowed down at the same time. Increase the residence time of the material in the mill and strengthen the grinding.

(3) adding the activated liner in the mill tail bin can effectively slow down the flow velocity of the material in the stern and enhance the grinding function of the small forging and improve the specific surface area of the product.

The grind tail grate plate is the 5mm special discharge grate plate of the small grate joint (which can be reconstructed on the original basis), and the diameter of the lifting plate is adjusted to control the flow rate of the material. The reverse end face of the double storeboard adopts a protective plate with a ventilated grate, which not only protects the stainless steel sieve plate from abrasive erosion but also strengthens the ventilation in the mill, promotes the qualified fine powder to be discharged in time and reduces the grinding phenomenon.

It is suitable for the ventilation speed in the mill, which is suitable for the wind speed of 0.8 ~ 1.0m/s, to shorten the residence time of the qualified fine materials in the grinding, and to promote the heat of micro powder and grinding in time to discharge the mill, so as to improve the grinding efficiency.

It is necessary to add a wind lock device and a flexible device for locking the wind.

In general, the use of loop flow technology can significantly improve the system's time output, reduce power consumption per unit product, and reduce production costs. The mill uses a pulse bag filter to remove dust, and the fan motor uses frequency conversion to adjust the wind speed in the mill to control the flow velocity and fineness of the material.

Scan£¬

Mobile phone view is more convenient